Flocculating agent for aluminum oxide

I.Performance index of product

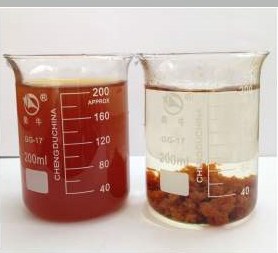

Flocculating agent for aluminum oxide is a type of chemosynthetic organic macromolecule polymer. This flocculating agent is easily soluble in water and can facilitate the agglutination of red mud particles through adsorption, bridging and electrical neutralization and therefore can speed up sedimentation. Using this flocculating agent in small amounts will bring about the quick separation of red mud and sodium chlorate solution. This product has been widely used in the washing and separation process for the production of gasified aluminum via Bayer process.

|

Product type |

Appearance |

Viscosity(cp.s) |

Density |

PH |

Flashing point(℃) |

Solid content(%) |

Ionic charge |

Molecular weight |

Dissolution duration(min) |

|

HK-100 |

Viscous liquid |

≥100 |

≥1.01 |

≥6.5 |

≥100 |

≥40 |

High negative ion |

Medium high |

≤30 |

|

HK-200 |

Viscous liquid |

≥150 |

≥1.05 |

≥7 |

≥100 |

≥35 |

High negative ion |

Medium high |

≤30 |

II. Property of HK-100

1. Low use level, good compatibility, high flocculation efficiency, quick sedimentation and large floccules;

2. Especially suitable for all the washing processes;

3. The flocculation effect is little affected by slurry density, temperature, PH value and other factors;

4. Convenient use, easy dispersion and quick dissolution.

III. Property of HK-200

1.High clarity of cleaning layer, low content of seston; the floccules are of low moisture content, high strength and anti-shearing;

2.Enable the separation and cleaning of China-made and imported bauxite slurry (especially high-iron bauxite);

3. The flocculation effect is little affected by the ingredient of sizing agent, concentration, temperature, PH value and other factors;

4. Convenient use, easy dispersion and quick dissolution.

IV. Direction for use

1. Prepare sodium hydroxide solution of 10% to 15%;

2. Mix the accelerator in the prepared aqueous slkali pot to prepare flocculant solution of 3%.

V. Instructions

1. The operator shall put on protective articles to prevent the skin from the contact of this product. Once it has contacted the skin, wash the skin with plenty of water immediately.

2. Avoid sprinkling this product on the ground. If so, clean it immediately, so as to avoid slippery ground and causing injury to personnel.

3. Warm water may speed up the solution of the product, but the temperate cannot be too high. If the temperature is too high, thermal degradation will be caused to the product, so that the application effect will be affected. Usually the temperature of the warm water shall be no higher than 50℃.

4. Agitation will facilitate dissolution. But too rapid agitation will lead to degradation and thus affect the application effect. So it is necessary to control the agitation intensity during dissolution.

5. It is advisable to store the prepared solution for no more than 48 hours.

VI. Packing and storage

1. This product shall be packed by IBC barrel with net weight of 1,000 kg. Different packing specification can be applied as per customer requirements.

2. Prevent the contact of this product and copper, iron, aluminum and other metals. When sealed and placed in a cool place, the validity term of the product can be six months.

3. Pay attention to sealing the packing during the shipping of the product. Transport by either bus or by sea is acceptable.

4. Try to avoid exposing this product to sunlight and avoid storing it outdoors. This product shall be stored in a dry and well-ventilated house.